One of the stories that got under covered thanks to the focus on Russian hacking was the experiment in 3D printed housing conducted in Russia by Apis Cor. It was able to deploy its large-scale truck carried printer in Russia in sub-zero weather and build a house in 24 hours by printing it in place using a cement polymer. Not only could this be used to rapidly rebuild a town devastated by a natural or manmade disaster, the resulting home could be better able to withstand high winds, heavy snows, and flooding, so it arguably would be more durable than the home it replaced.

Let’s talk about printed homes this week.

3D Printed Homes

Surprisingly, 3D printed homes aren’t new, but 3D printing at this scale is largely done in factories to build panels which then have to be shipped and assembled on site after a slab or foundation is in place. This significantly increases both the cost of the home and the time it takes to build it. This is actually how most 3D printing projects have traditionally started out; due to the limitations of the technology, you don’t print the entire thing, you print parts that need to then be manually assembled, which falls far short of what people generally think of when you tell them an object was 3D printed.

Apis Cor

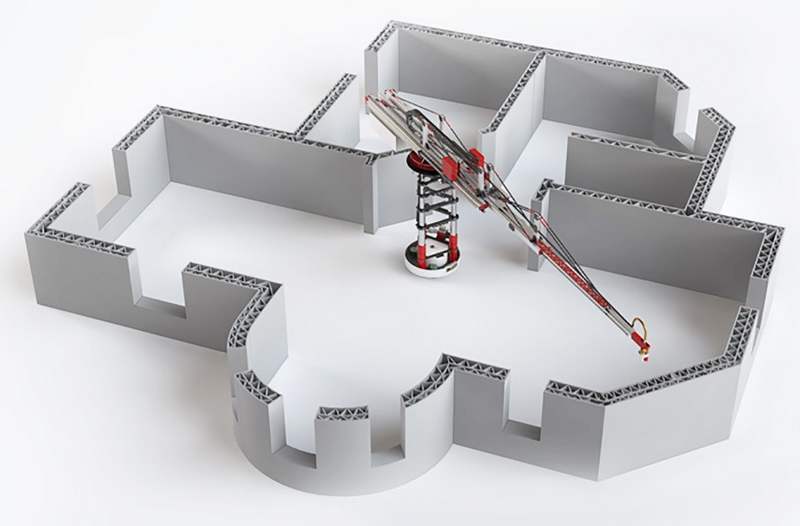

What makes the Apis Cor solution very different is the fact that it uses a central tower crane-like arm which is placed on site. The arm is then hooked up to a supply of concreate polymer which it then extrudes to build the inside and outside walls of the home in one fluid process. Be aware that during this time workers do insert fiberglass reinforcement bars, and trim items like doors and windows still need to be installed manually, as does plumbing and electrical wiring. However, this last could all be prefabricated and rapidly assembled on site. (You can see a video of how it works here).

What I think is very interesting in the printer arm is that it follows the convention of a centrally positioned skyscraper crane. With this design,

Image via Apis Cor

Image via Apis Cor

they have been able to construct towering skyscrapers that challenge the limits of engineering simply by extending the crane arm out and lifting the crane up as the building is built. You could do the same thing with this printer arm and potentially build skyscrapers a floor a day. Granted, I expect you’d want some extra curing on the lower floors, but could you imagine having a 60-floor skyscraper fully fleshed out in anything close to 60 days? Someone could go on a two-month sabbatical and come back with an entirely different skyline.

This could be particularly useful for fast shelters as a part of disaster recovery, to house refugees, or to set up military bases quickly. If you had 30 arms you could potentially build 30 rigid structures a day. Imagine this being used to get ready for the Olympics, for instance. You could wait till around six months out and then build the housing for the event based on how many athletes are actually coming.

Trump’s Wall

You know, it strikes me that if you wanted to build a wall between countries, this same technology on a truck mount could likely build a wall between countries incredibly quickly. It looks like each machine could likely build a 15’ high by 200’ long section a day. Thirty machines could then build about 6,000 feet in a day and that would be a mile a day. Granted, this would mean 2,000 days, but 60 machines could cut that in half and 120 machines in half again, coming close to 500 days or under two years. You might even be able to optimize the 3D printer for walls, automate it (make it autonomous) and run the result 24/7, potentially massively reducing the build time and related labor costs.

Wrapping Up

I think yet another industry is about to be massively changed by technology advances. That is the building industry, and this is really only the start. Different designs in arms, tracks, and transports could turn what is an interesting idea for small homes into a fantastic idea for large buildings and even scary long walls. First areas of impact will likely be for disaster recovery, military, and other semi-permanent structures, but these could easily replace mobile homes with alternatives that were far less likely to be blown away in a storm. In the end, this adds to an effort to print cars and builds on top of changes like human carrying drones and artificially intelligent robots that should have us well on the way for the next industrial revolution by the end of the decade. You’d better love change because there is going to be a ton of it!