There are many ways to turn a CAD design into a physical reality. Both subtractive and additive manufacturing can be used to create parts with digital precision. For the best results, choose a manufacturing process that aligns with the structural and economic needs of your design.

CNC Machining or 3D Printing?

Most parts can be made with either 3D printing or CNC machining. CNC production will usually create higher quality parts if the design can easily be made with subtractive manufacturing. However, due to cost, complexity, or production speed, 3D manufacturing might be a better choice for your product.

The Benefits of CNC machined parts

CNC machining is a subtractive manufacturing process. A CNC machined product is created by selectively cutting a block of material until it is in the desired shape. This manufacturing method is best used to create durable parts and structural components.

The most common materials used for CNC manufacturing are stainless steel and aluminum. Brass, polycarbonate, ABS, and nylon are also viable options. CNC products have great structural integrity and can be produced with extremely smooth finishes.

The CNC manufacturing process has higher dimensional accuracy and produces detailed parts with better mechanical properties. However, increased complexity on a CNC machined part always results in a higher cost. For this reason, CNC is better for end-use products but less appropriate for quick prototypes and complicated geometric designs.

Choose CNC machining if:

- The part can easily be produced with subtractive manufacturing.

- Precise details, sharp angles, and a smooth finish are preferred.

- High structural integrity and temperature resistance are needed.

- The increased cost is acceptable for a better final product.

The Benefits of 3D Printed Parts

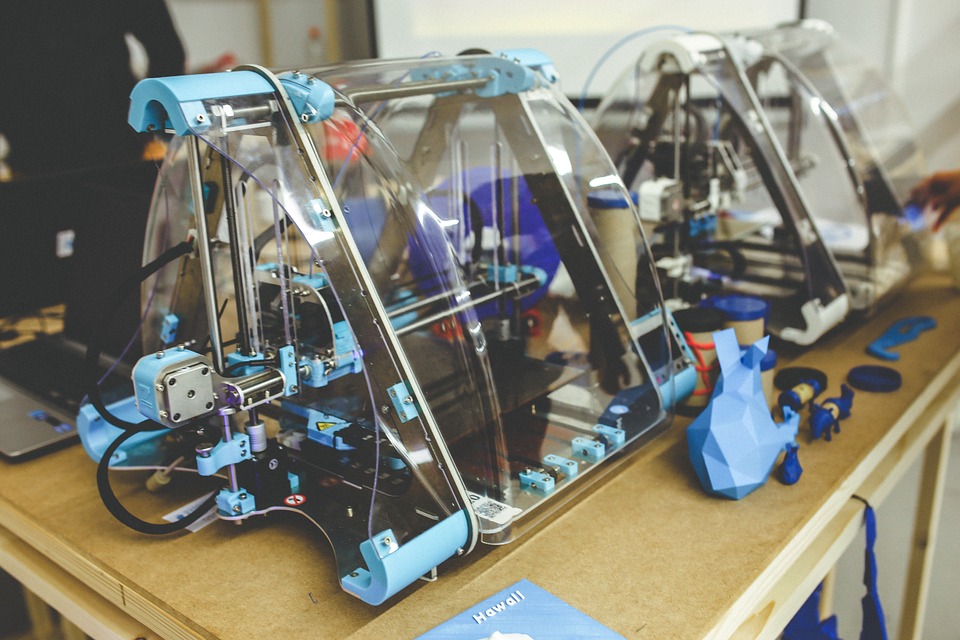

3D printing is an additive manufacturing process. A 3D printer adds layers of material until the desired shape is formed; post-processing may be needed to remove support structures or to achieve the desired finish. This process is best used for prototypes, models, and complicated geometric shapes.

3D printed objects can be made from a wide variety of materials with different properties. Each printing process uses specific materials and has its own best-use scenarios. Common materials include resin, nylon, and PLA; however, metal printing is also an option.

Geometric complexity does not incur additional costs with additive manufacturing. Almost any CAD model can be reproduced with a 3D printer. Items can be printed within 24 hours, so 3D manufacturing is often used when short lead time is essential.

Select 3D printing when:

- The geometry of the design is extremely complex.

- The product should be made from flexible materials and alloys.

- A few copies of the part are needed.

- Reduced costs are essential for production.

- An extremely fast turnaround is desired.

What if higher part quantities are needed?

Subtractive and additive manufacturing are most cost-effective when used to produce small batches of individual parts. Both processes have low start-up costs; single and multiple parts can typically be created for the same price per unit.

If hundreds of identical parts are needed, traditional forming technology is usually more cost-competitive. Due to the economics of scale, processes like injection molding can create high quantities of parts for a lower price per unit.

In general, use CNC machining or 3D printing when you need less than 300 parts. If you need more than that, choose injection molding.

How to get your parts fast in the technology you Need

No matter which technology your design needs, a manufacturing platform is the easiest way to get quick and effortless production. 3D Hubs offers CNC machining, injection molding, and 3D printing service available at the click of a button.

To create your part, simply upload your CAD file to the online manufacturing tool. The tool will instantly generate a quote and a free Design for Manufacturing analysis. The DfM analysis will automatically check your design for viability with the chosen manufacturing process.

3D Hubs partners with manufacturers across the globe to deliver high-quality custom products. We offer both 3D printing and CNC machining services at competitive prices and with exceptionally low lead times. Get an instant CNC quote for your product today, or visit our knowledge base for more information about our manufacturing capabilities.