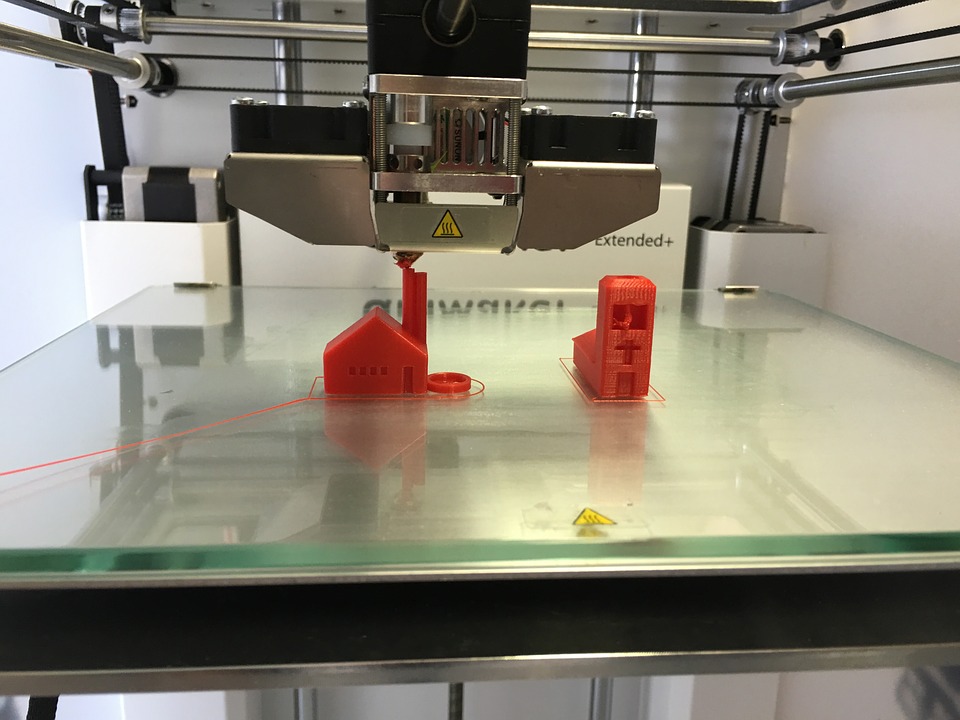

Custom 3D printing Canada can be done with a wide range of materials. For example, nowadays a lot of companies decide to use a type of metal in order to manufacture a three dimensional product with the help of a 3D printer. On the other hand, you could also decide to use a plastic type when hiring a 3D printing service UK. There are multiple metals and plastics available, which one is the best purely depends on your 3D model. A flexible filament might be the best option, although this does not have to be the case.

What are flexible filaments?

As mentioned above, a flexible filament is one of the materials that can be used to 3D print an item. These are materials with a mix of rubber properties and rigid plastic. This combination is known as a thermoplastic elastomer, although its abbreviation TPE is used often instead. These thermoplastic elastomers act in a similar manner to rubber. They can be twisted and stretched to a large extent, while they definitely will not break. There are so many different flexible filaments out there for you to use. They have different characteristics and properties. For example, some are more elastic than the others. The most commonly used flexible filament is the thermoplastic polyurethane, often referred to as TPU.

What are the advantages of flexible filaments?

3D printing flexible filaments has some big pros for its users. This includes the great elasticity, which has already been mentioned. If the filament needs to be stretched, bent, and maneuvered, using a TPE is definitely advised. On top of that, a material that behaves like rubber will dampen vibrations. This can be handy in products for industrial or mechanical applications. Impact resistance is another benefit of the flexible filaments. Even if the impact is very significant, it often does not deform items made of a flexible filament like thermoplastic polyurethane.

What are the disadvantages of flexible filaments?

Of course, flexible filaments have some cons as well. For example, it does not offer as much post-processing possibilities as other materials. This means that your finished print can barely be adjusted after the 3D printer has done its job. Another drawback of the flexible filaments is that they are more difficult to print than other material types. They namely have different characteristics, so stringing might occur. Obviously, this makes it a less suitable option for aesthetic prints.