You may already know that CNC machining is an umbrella term for a few different techniques. Want to use one of these processes? Go for a CNC quote! However, you probably did not know that sheet metal fabrication is an umbrella term for a plethora of processes as well. By going to sheet metal services you will learn more about this. On top of that, below the three main types of sheet metal fabrication will be outlined as well.

Forming

When using forming material will not be subtracted. Instead it will be reshaped to the desired contours. Forming includes processes such as stamping, stretching, bending, and roll forming. Stamping uses single or progressive dies to press the metal into the desired shape. The technique uses two dies, while the metal sheet will be pressed between them. Stretching pulls metal apart via a stretcher, as the name implies. Bending can be done by hand, but usually the metal sheet will be bent with the help of press brakes. Roll forming is similar in its result as bending. In this process the sheet of metal will pass through a pair of rolls so it is formed into the right shape.

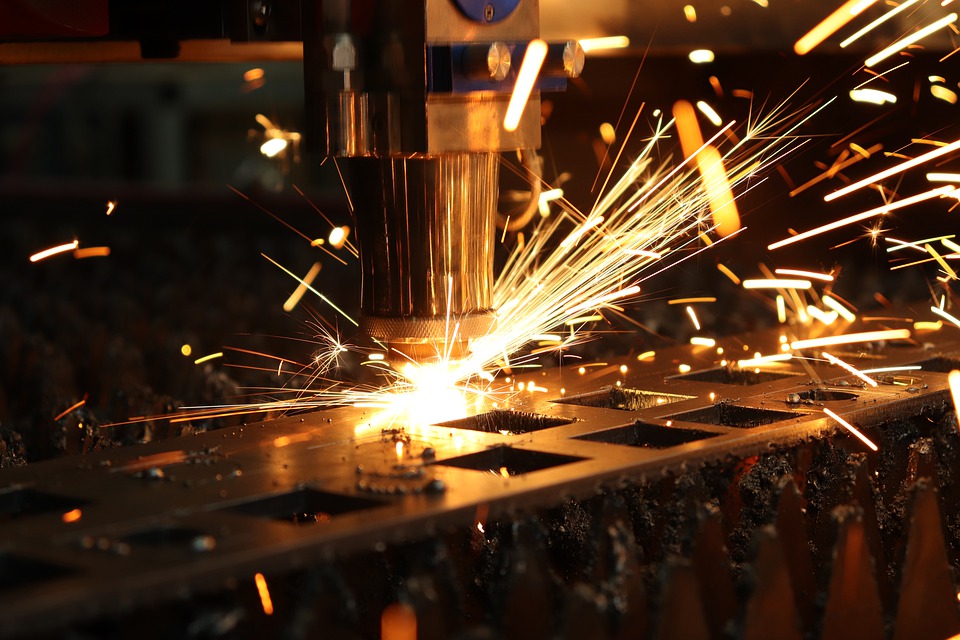

Cutting

Cutting consists of two different types: with shear and without shear. Shear cutting is commonly used for nonindustrial end products because they are less precise. Processes used for shear cutting are cutting, blanking, and shearing. Non-shear cutting is thus more accurate, so it is used mostly for industrial products. Even airplane wings are made this way. There are multiple non-shear cutting processes, including plasma, waterjet cutting, laser beam, and machining. Laser cutting is quite spectacular actually. This process uses a focused beam of light to cut through or engrave a metal material.

Joining

Joining also consists of many different processes, including welding. This comes in multiple forms. It functions by fusing the metal sheets together through melting them. A filler will be added as well. Another joining process is riveting. This relies on small metal parts to join metal sheets by embedding them through both sheets. Brazing is similar to welding, although it acts in a different way. It namely melts a filler, while the sheets will not be melted during this process. Another joining technique is using adhesives. These hold together metal sheets either alone or in conjunction with another joining method.